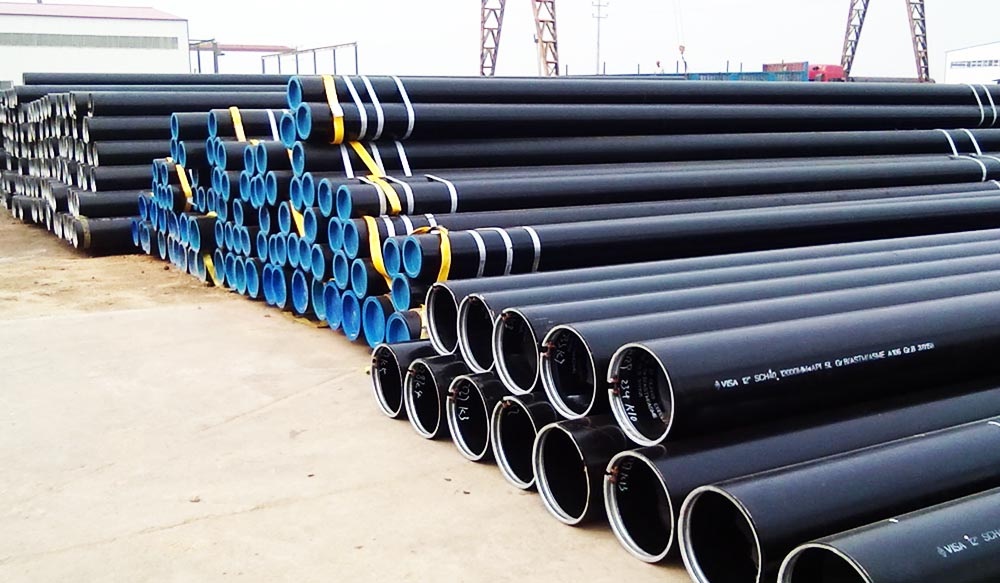

When embarking on industrial projects that require the transport of gas or liquid under pressure, the integrity and reliability of your piping system are paramount. In these instances, API 5L pipes, regulated under the American Petroleum Institute (API) specification 5L, are often the go-to choice for companies around the globe. Choosing the right API 5L pipes supplier and manufacturer is crucial, and that’s where Trio Steel, a leader in the industry, comes into play. But beyond selecting the right supplier, there’s an essential decision that project managers face – whether to opt for seamless or welded API 5L pipes. This comprehensive guide aims to provide clarity to this question, drawing on the expertise and offerings of Trio Steel as the API 5L PIPES SUPPLIER AND MANUFACTURER.

Seamless API 5L Pipes

Manufacturing Process: Seamless pipes are manufactured via extrusion, which involves heating a solid steel billet and piercing it to create a hollow tube without any joints or welding. This process provides the seamless pipe with a smooth and uniform structure.

Advantages:

- Strength: Due to their uniform homogeneous structure, seamless pipes boast superior strength and are capable of withstanding higher pressures and loads.

- Durability: Seamless pipes are more resistant to corrosion and wear-and-tear, making them a durable option for high-pressure applications.

- Versatility: These pipes can be used in a wider range of applications, from high-temperature steam services to high-pressure gas lines, thanks to their enhanced properties.

Drawbacks:

- Cost: The complex manufacturing process of seamless pipes often results in a higher cost compared to welded pipes.

- Limited Size Range: Creating large diameter seamless pipes is challenging, which may limit their availability for certain applications.

Welded API 5L Pipes

Manufacturing Process: Welded pipes are produced by coiling steel strips and welding them longitudinally across their lengths. Recent advancements in manufacturing technologies, such as Electric Resistance Welding (ERW), have significantly improved the quality and reliability of welded pipes.

Advantages:

- Cost-Effectiveness: Welded pipes are more economical than seamless pipes, making them an attractive option for projects with budget constraints.

- Availability: They can be manufactured in large diameters and lengths, offering flexibility for large-scale projects.

- Efficiency: Modern welding techniques ensure that welded pipes have a good surface finish and precise dimensions.

Drawbacks:

- Strength Concerns: Although the quality of welded pipes has improved drastically, they are generally considered to be less strong than seamless pipes, particularly in high-pressure applications.

- Inspection and Testing: Welded pipes often require more rigorous inspection and testing to ensure the integrity of the welds.

Trio Steel: Your API 5L Pipes Supplier and Manufacturer

Trio Steel, a renowned API 5L pipes supplier and manufacturer, stands at the forefront of providing high-quality seamless and welded API 5L pipes tailored to meet the specific needs of various industries, including oil and gas, petrochemical, and water treatment plants, among others.

Quality Assurance: At Trio Steel, every pipe undergoes stringent quality checks and meets the API 5L standards, ensuring superior performance in demanding environments. Whether you’re opting for seamless or welded pipes, Trio Steel assures a product that combines durability with optimal performance.

Custom Solutions: Understanding that no two projects are the same, Trio Steel offers customized solutions that match your project specifications. From specific diameters and wall thicknesses to unique grades of steel, Trio Steel can provide pipes that precisely fit your technical requirements.

Expert Guidance: Choosing between seamless and welded API 5L pipes can be a complex decision, influenced by factors like project scale, budget, and intended application. Trio Steel’s team of experts is always ready to advise you on the most suitable option for your project, drawing upon years of experience and technical expertise.

Environmentally Conscious Manufacturing: In today’s eco-aware world, Trio Steel is committed to sustainable manufacturing practices, ensuring that the production of both seamless and welded pipes has a minimal environmental footprint. This commitment extends to every facet of their operation, from raw material selection to production processes.

Commitment to Innovation

Trio Steel doesn’t just rest on its laurels as a reputable API 5L pipes supplier and manufacturer; it continuously seeks to innovate. By investing in the latest manufacturing technologies and research, Trio Steel ensures that both its seamless and welded API 5L pipes remain at the forefront of quality, efficiency, and sustainability. This commitment to innovation translates into direct benefits for your projects, including enhanced performance and cost savings over the long term.

Tailored Solutions for Diverse Industries

Understanding the needs of different industries is at the heart of what makes Trio Steel an exceptional API 5L pipes supplier and manufacturer. Whether it’s the oil and gas sector, requiring pipes that can withstand extreme pressures and temperatures, or water treatment facilities looking for reliable and corrosion-resistant pipes, Trio Steel has the expertise and inventory to meet these diverse needs. Their tailored approach ensures that each client receives guidance and products that precisely match their project specifications, no matter how complex or unique.

Global Reach, Local Service

In today’s globalized world, having a reliable API 5L pipes supplier and manufacturer that can deliver on an international scale is critical. Trio Steel not only has a global reach, ensuring the availability of their top-quality seamless and welded API 5L pipes around the world but also maintains a high level of local service. This means regardless of where your project is located, you can expect timely delivery, personalized service, and local expertise, ensuring that distance is never a barrier to achieving project success.

By choosing Trio Steel for yourmless and welded API 5L pipe needs, you are opting for []partner who not only provides products of the highest caliber but also brings a depth of expertise and innovation to the table. This partnership empowers your projects to run smoothly, efficiently, and sustainably, underpinned by the reliability of Trio Steel’s high-quality API 5L pipes.

Conclusion: Making the Right Choice for Your Project

Deciding between seamless and welded API 5L pipes ultimately comes down to understanding your project’s specific needs. Seamless pipes offer superior strength and durability, making them ideal for high-pressure applications, while welded pipes provide cost-effectiveness and versatility for a broad range of uses.

By partnering with Trio Steel, an esteemed API 5L pipes supplier and manufacturer, you are ensured access to high-quality piping solutions that are designed to meet the rigorous demands of your projects. Their commitment to excellence, coupled with comprehensive support and custom solutions, positions Trio Steel as a pivotal partner in the success of your operations.

As the industry continues to evolve, the debate between seamless vs. welded API 5L pipes will persist, but with the right information and a trusted supplier like Trio Steel, you can make an informed decision that best suits the intricacies of your project, ensuring efficiency, safety, and optimal performance. Whether your application calls for API 5L X42, API 5L X46, API 5L X52, API 5L X56, API 5L X60, API 5L X65, API 5L X70, or API 5L X80, Trio Steel offers a wide array of both seamless and welded pipes to meet the demanding requirements of various industries and sectors.