The clean bench or laminar flow cabinet is a critical tool in numerous industries, ensuring a sterile environment through a consistent stream of filtered air. Originally used primarily in research and manufacturing, these cabinets are now vital in sectors like aerospace, bioscience, pharmaceuticals, and food production.

These benches feature a non-ducted air filtration system that provides a contaminant-free area for precise tasks. Their appeal has grown due to several benefits: they are eco-friendly as they recycle air, emit no hazardous byproducts, and are cost-effective to install and maintain, usually requiring only yearly filter replacements. The design of these benches is user-friendly, allowing immediate operation without the need for extensive HVAC setups. Moreover, they are mobile, plug into standard outlets, and include safety features that meet ACGIH standards, making them versatile for various settings.

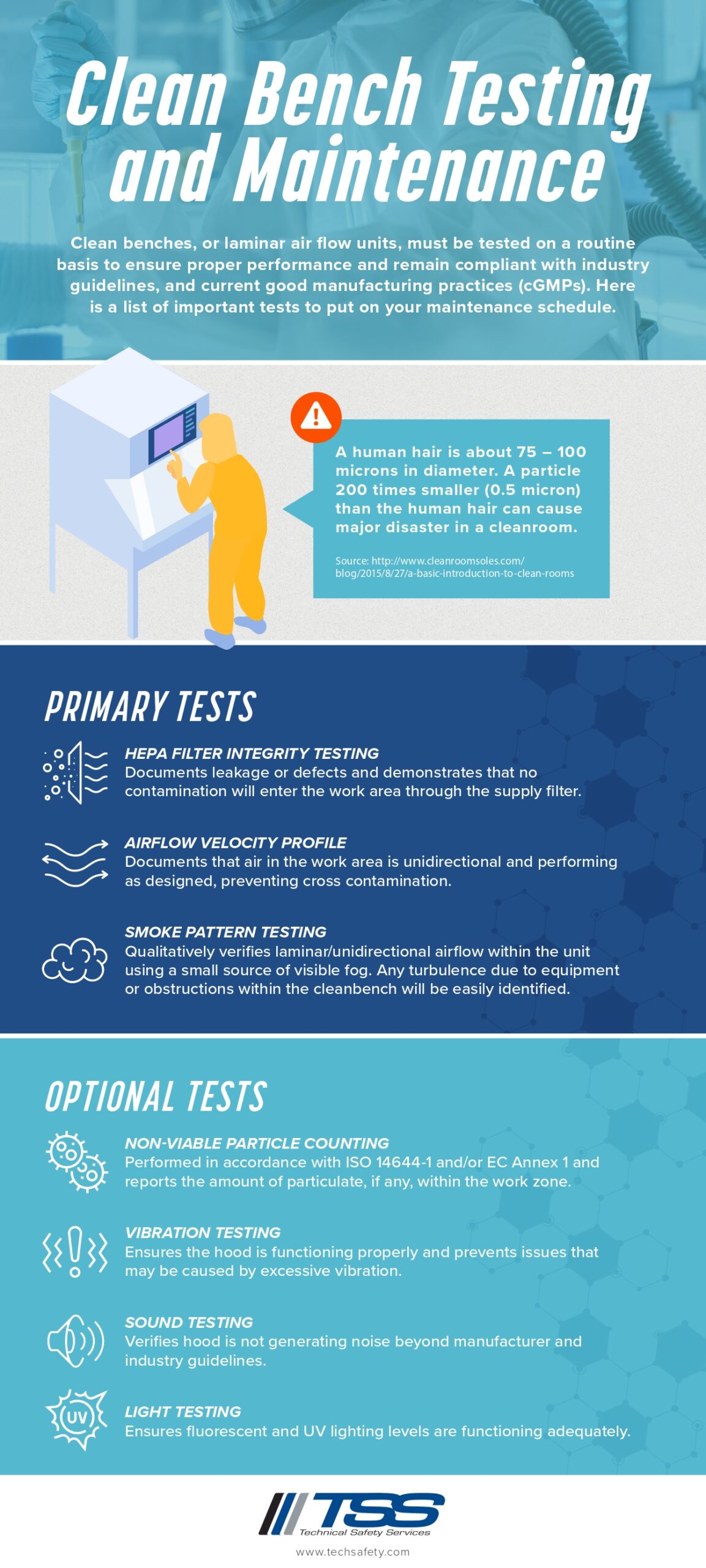

However, despite their advantages, there is often a lack of understanding about the maintenance these benches require to remain in peak condition and adhere to regulatory norms. For comprehensive guidance on the maintenance of clean benches, consult the detailed infographic below provided by Technical Safety Services.

Infographic created by Technical Safety Services