Hazardous goods packaging is the process of designing, testing, and manufacturing containers that can safely transport hazardous materials. These materials can include chemicals, pharmaceuticals, and other substances that pose a risk to human health and the environment.

The packaging of hazardous goods is regulated by international, national, and local regulations, which specify the requirements for the design, construction, and performance of the packaging. These regulations aim to ensure that hazardous goods are transported safely and securely, and that the risks associated with these materials are minimised.

The Importance of Hazardous Goods Packaging

The importance of hazardous or dangerous goods packaging cannot be overstated. Proper packaging is essential to ensure that hazardous materials are transported safely and securely, and that they do not pose a risk to human health and the environment.

Hazardous goods packaging also plays a critical role in ensuring supply chain security. The packaging of hazardous goods must be designed to withstand the rigours of transportation, including vibration, shock, and temperature changes. This ensures that the materials remain stable and do not leak or spill during transport, which could result in a serious safety hazard.

Types of Hazardous Goods Packaging

There are various types of dangerous goods packaging, each designed to meet specific requirements. Some of the most common types of hazardous goods packaging include:

- Drums: Drums are commonly used to transport hazardous liquids, such as chemicals and pharmaceuticals. They are typically made of steel or plastic and are designed to withstand the rigours of transportation.

- Intermediate Bulk Containers (IBCs): IBCs are large containers used to transport hazardous liquids and solids. They are typically made of plastic or metal and can hold up to several thousand litres of material.

- Boxes and Cartons: Boxes and cartons are used to transport hazardous solids, such as chemicals and pharmaceuticals. They are typically made of corrugated cardboard or plastic and are designed to withstand the rigours of transportation.

- Bags: Bags are used to transport hazardous solids and liquids, such as chemicals and pharmaceuticals. They are typically made of plastic or paper and are designed to withstand the rigours of transportation.

Testing and Certification of Hazardous Goods Packaging

Hazardous goods packaging must undergo rigorous testing to ensure that it meets the requirements of international, national, and local regulations. This testing includes performance testing, such as drop testing and vibration testing, as well as environmental testing, such as exposure to extreme temperatures and humidity.

Once the packaging has been tested and meets the requirements of the regulations, it must be certified. Certification ensures that the packaging is safe and meets the requirements of the regulations.

Certification is typically carried out by independent third-party organisations, such as the United Nations Committee of Experts on the Transport of Dangerous Goods.

The Role of Technology in Hazardous Goods Packaging

Technology plays a critical role in hazardous goods packaging. Advances in technology have led to the development of new materials and designs that can improve the safety and security of hazardous goods transportation.

For example, new materials, such as nanomaterials and biodegradable materials, are being developed that can improve the strength and durability of hazardous goods packaging while also reducing the environmental impact of the packaging.

In addition, new technologies, such as sensors and tracking devices, are being developed that can monitor the condition of hazardous goods packaging during transport. This can help to ensure that the packaging remains intact and that the materials are transported safely and securely.

Conclusion

Hazardous goods packaging is a critical aspect of the supply chain, and it plays a significant role in ensuring supply chain security. Proper packaging is essential to ensure that hazardous materials are transported safely and securely, and that they do not pose a risk to human health and the environment.

Hazardous goods packaging must undergo rigorous testing and certification to ensure that it meets the requirements of international, national, and local regulations. Advances in technology are also playing a critical role in improving the safety and security of hazardous goods transportation.

Overall, it is essential to recognise the significance of hazardous goods packaging in ensuring supply chain security and to continue to invest in the development of new technologies and materials to improve the safety and security of hazardous goods transportation.

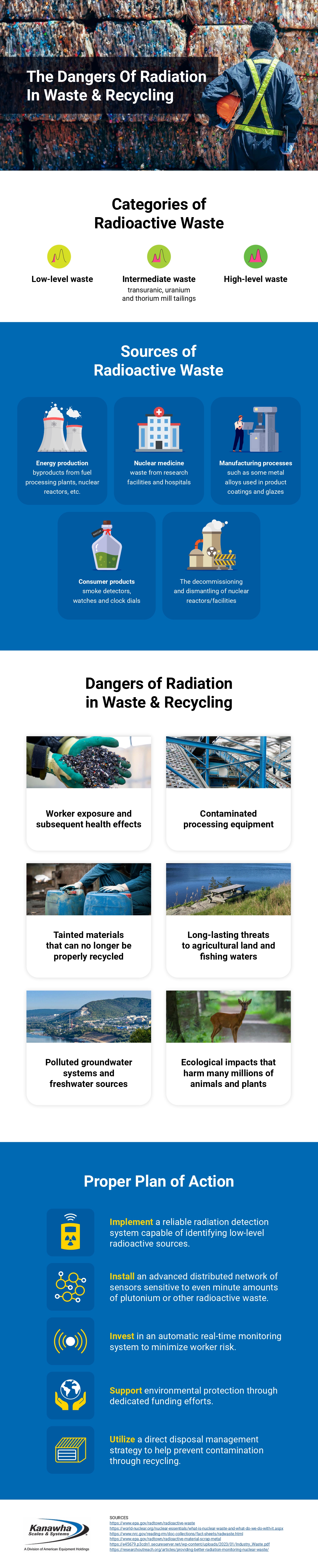

Hazardous materials can find their way into recycling, posing a danger to workers. To learn more on the dangers of radiation in waste and recycling, please see the accompanying resource.

Infographic provided by truck scales experts, Kanawha Scales & Systems