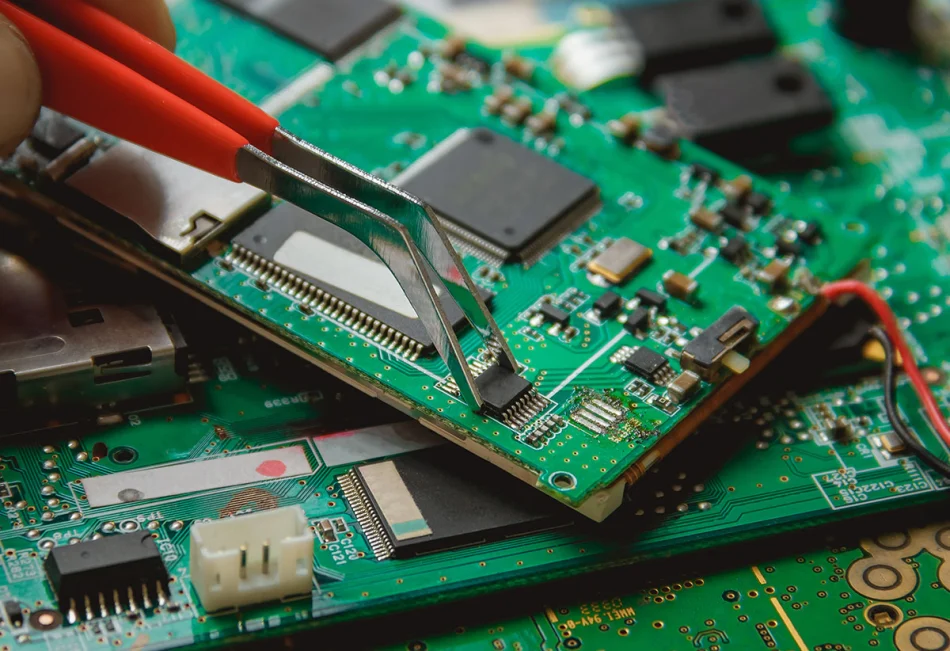

If you are in the electronics manufacturing business, you may want to consider outsourcing PCB manufacturing to companies that can do the job more effectively and accurately. There are many PCB manufacturing companies that have invested heavily in printing equipment for PCBs. These companies have also hired the best specialists to operate these machines. This means that they can accurately design and print the type of PCBs you want on a large scale. The beauty of all this is that you can save a considerable amount of money on PCBs. If you are wondering – how much does it cost to manufacture a PCB board? – you have come to the right place.

Factors Affecting PCB Manufacturing Costs

1. Type of PCB

A PCB can be printed on one side or on both sides. It costs more to print both sides of a PCB board than one side. Depending on the type of PCB you want to manufacture for your device, you should know that the manufacturing cost will differ.

2. Size of PCB

Larger PCBs require more material than smaller PCBs. It also takes longer to print larger boards than smaller ones. The amount of work required to complete the PCB manufacturing process for larger boards is also greater. As a result, it will cost you more to print larger boards than smaller ones. In other words, manufacturing costs increase with the size of the PCB.

3. Circuit Design

Some circuits require larger boards with simple circuit designs while others require smaller boards with more elaborate circuit designs. The design of a circuit affects the cost of manufacturing a printed circuit board, with simple circuits costing less than complex circuit designs.

4. Choice of Manufacturing Company

There are many PCB manufacturing companies in existence and they are all different. When looking to save money on PCB manufacturing, it is crucial you spend time comparing the rates charged by different firms on PCB manufacturing services. This will help to ensure you find an affordable service provider.

5. Assembly Cost

All PCB manufacturing companies usually test all the PCBs they manufacture before delivering the PCBs to the client. This service does not come with an extra cost. However, if you would like to also have the boards assembled, it is recommended you negotiate a great deal. The cost of PCB manufacturing will increase if you also require assembly services. However, the overall cost of printing and assembling PCBs will be much lower. That is why consumers are advised to get PCB manufacturing and assembly services from the same company.

Since there are many manufacturers, like avanticircuits.com, out there, it’s crucial you consider a variety of factors before making a decision. For instance, you should give special consideration to firms that offer customer satisfaction guarantees as well as a money-back guarantee. In case of defective boards, the manufacturers will either offer financial compensation or print additional replacement boards at their own cost. This will help to ensure you get the best possible value for money.